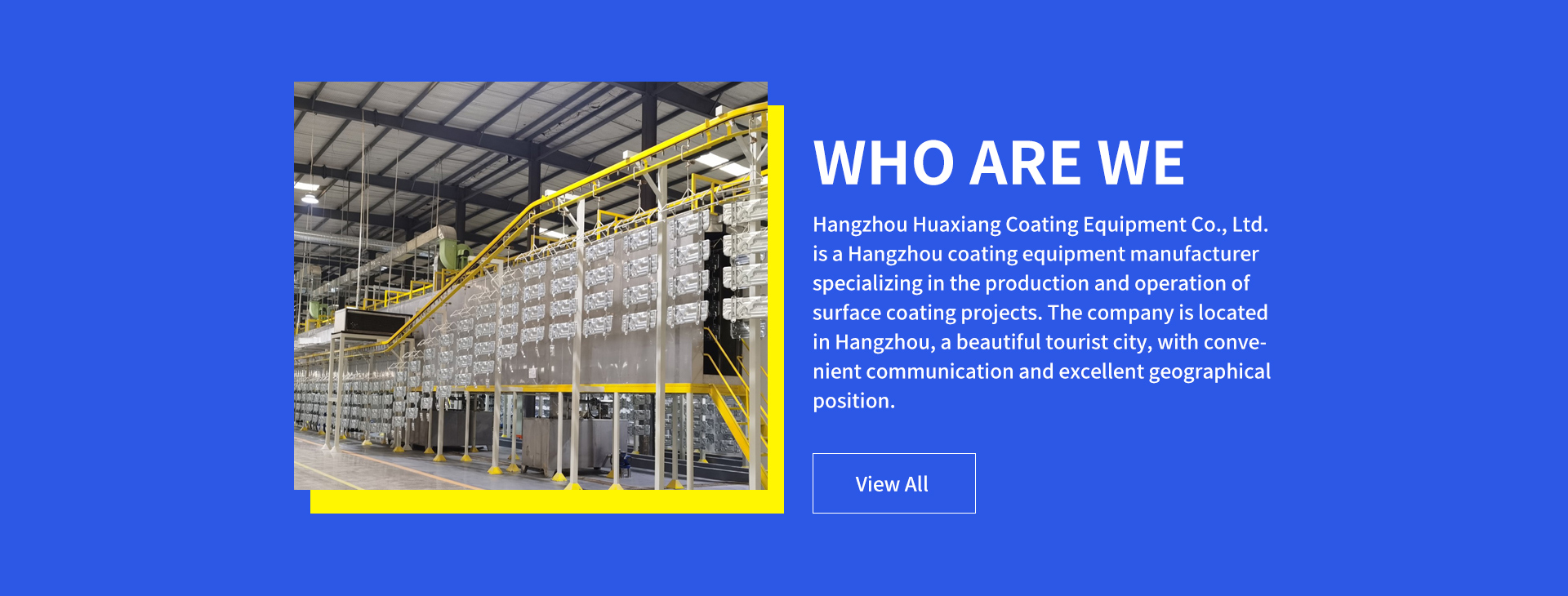

1. Industrial Powder Paint Machine Overview

Industrial Powder Paint Machines are high-capacity systems designed for mass production of coated metal products. Core components include multi-axis robotic arms, electrostatic spray guns, conveyorized ovens, powder recovery booths, PLC controllers, and IoT-enabled monitoring. These systems prioritize speed, precision, and minimal waste in continuous manufacturing environments.

2. Key Applications

Automotive: Coating car frames, wheels, and engine parts.

Appliances: Ovens, refrigerators, and washing machine panels.

Aerospace: Aircraft components requiring corrosion-resistant finishes.

Construction: Architectural aluminum extrusions, steel beams.

3. Industrial Powder Paint Machine Pricing

| Type | Price Range | Features |

|---|

| Mid-range systems | 200,000–500,000 | Basic robotics, 80–90% powder recovery. |

| High-end lines | 750,000–2 million+ | Customizable PLCs, 99% recovery, IoT integration (e.g., Durr EcoStar Pro). |

Brands: Durr, Eisenmann, Gema (Switzerland), and Nordson dominate the premium market.

4. Operational Workflow

Pre-treatment: Degrease and phosphate-clean parts.

Coating: Robotic guns apply electrostatically charged powder (60–100 kV) at 20–40 m/min conveyor speed.

Curing: Infrared or convection ovens bake coatings at 150–200°C (302–392°F).

Recovery: Cyclone filters reclaim 95–99% of overspray for reuse.

5. How to Choose an Industrial Powder Coating System

Throughput: Select systems rated for 1,000–5,000 parts/day.

Powder Type: Ensure compatibility with epoxy, polyester, or hybrid powders.

Energy Efficiency: Opt for recuperative ovens reducing energy use by 30%.

Compliance: Look for ISO 9001, OSHA, and EPA certifications.

6. Safety and Maintenance

7. Advantages Over Traditional Methods

Speed: Coat 10x faster than manual spraying.

Waste Reduction: Reclaim systems cut powder use by 40–60%.

Consistency: ±5 µm coating thickness tolerance.

Sustainability: VOC-free process vs. liquid paints.

8. Industrial Powder Paint Machine Q&A

Q: Can these machines handle mixed-batch production?

A: Yes—advanced PLCs allow quick reprogramming for different part geometries.

Q: What’s the typical ROI period?

A: 1.5–3 years for high-volume manufacturers.

Q: Are industrial systems compatible with non-conductive materials?

A: No—pre-treatment (e.g., conductive primers) is required for plastics.

Q: How much floor space is needed?

A: 500–2,000 sq ft, depending on conveyor length and booth size.

Q: Do they require specialized operators?

A: Yes—technicians need training in robotics and PLC programming (e.g., Fanuc certifications).

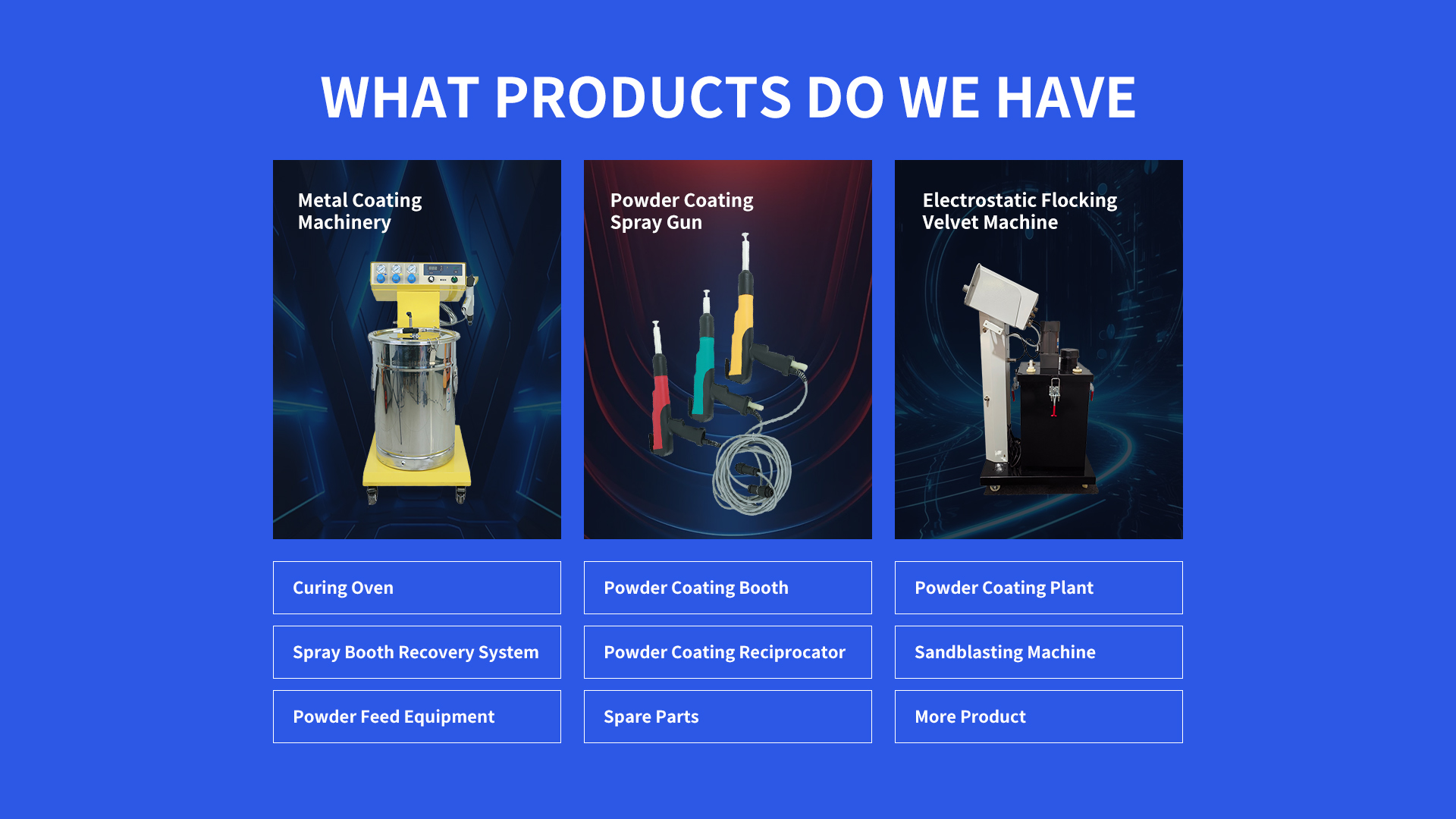

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com